Laser Cutting

What is Cutting With Laser?

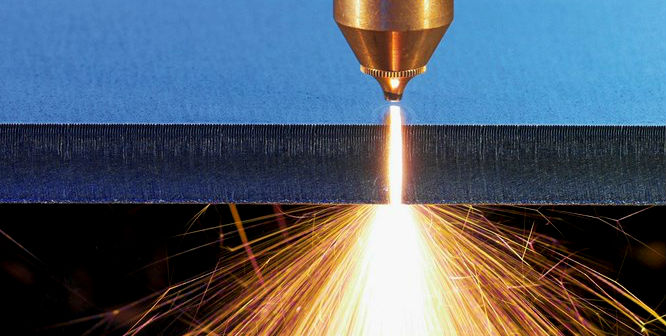

Laser cutting is essentially a thermal process in which a focused laser beam is used to melt material in a localized area. To remove the molten material a coaxial gas jet is used to create the notch. A continuous cut is produced by moving the laser beam or the workpiece under CNC control.

There are three main types of laser cutting: fusion cutting, flame cutting, and remote cutting.

In fusion cutting,an inert gas (typically nitrogen) is used to expel the molten material. Nitrogen gas reacts exothermically with the molten material.

Oxygen is used as auxiliary gas in flame cutting. This, in addition to exerting mechanical force on the molten material, is exothermic, which increases the energy input to the process.creates a reaction.

In remote cutting, the material is partially vaporized (cut off) by a high-intensity laser beam, allowing thin sheets to be cut without auxiliary gas.

The laser cutting system can also be combined with three-axis flatbed systems for three-dimensional laser cutting, or offline CAD/CAM systems controlling six-axis robots.suitable for work.

Thanks to improvements in sharpness, edge steepness and heat input control, laser processing is increasingly replacing other cutting techniques such as plasma and oxy-fuel.

Fiber Lasers and Advantages

Fiber lasers are members of a family called "solid state lasers". In solid state lasers, the beam is produced by a solid medium. Fiber lasers, disc lasers and Nd:YAG lasers are in the same category.

A fiber laser beam is produced by an array of laser diodes and focused into the fiber. The rays from many laser diodes are collected by fiber combiners and the active fiber is pumped to be amplified. The amplified beam is carried by the transmission cable called QBH and transmitted to the cutting head. By means of the optics in the cutting head, the beam diameter is reduced and focused on the cutting material.

Fiber laser sources have the following advantages:

Unlike a conventional CO2 resonator, a fiber laser source does not have any moving parts (e.g. fans for gas circulation) or mirrors in the light producing source. This is a huge advantage in terms of reducing maintenance requirements and operating costs.

Fiber lasers are typically two to three times more energy efficient than CO2 lasers of the same power. A fiber laser can cut thin sheets faster than a CO2 laser of the same power. This is because the fiber laser wavelength is better absorbed in the cut material.

Fiber lazerler, aynı güce sahip CO2 lazerlerden tipik olarak iki ila üç kat daha fazla enerji verimlidir.

Bir fiber lazer, aynı güçteki bir CO2 lazerinden daha hızlı bir şekilde ince tabakaları kesebilir. Bunun nedeni, kesilen malzemede fiber lazer dalga boyunun daha iyi emilmesidir.

Fiber lasers can cut reflective/glossy materials without interrupting the process and being affected by back reflections that damage laser sources (resenators) thanks to their back reflection protection. This enables seamless cutting of copper, brass and aluminum.